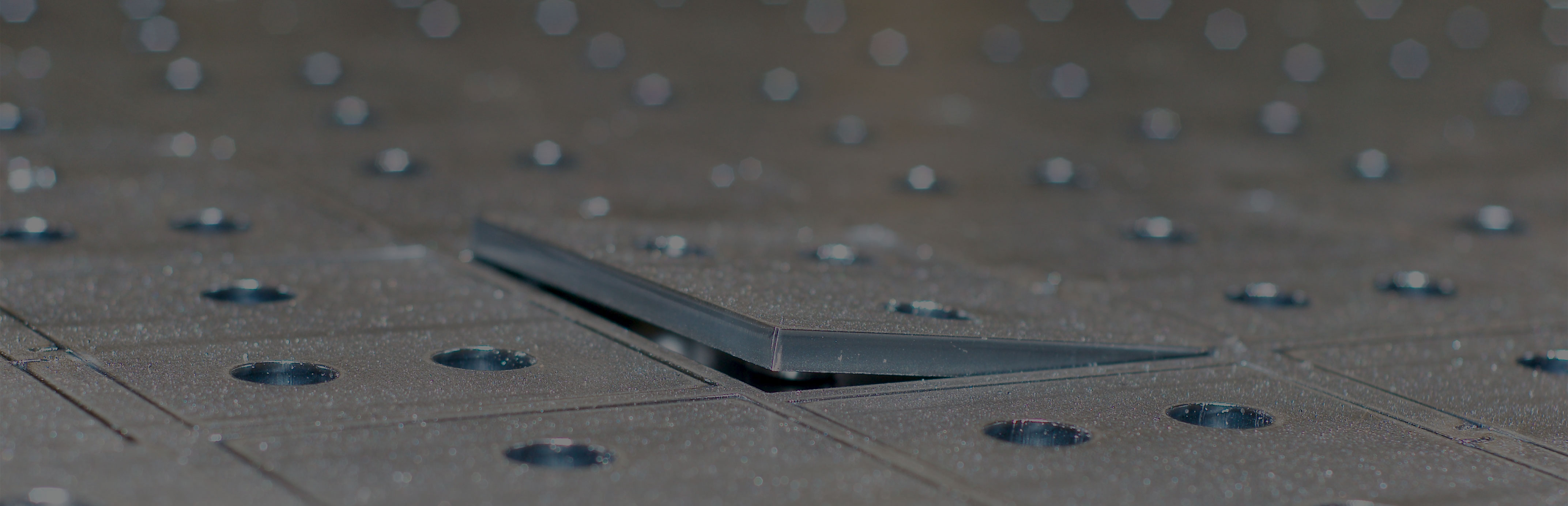

Our latest laser cutting technology allows us to provide our customers with the highest quality of manufacturing processes. This technology enables us to create in-house custom jobs for your needs. We pride ourselves with great service to meet the specific needs of our clients both locally and further afield.

Methods and process

A laser cutter is quickly becoming one of the most effective alternatives to many traditional metal cutting methods, providing many benefits over traditional methods.

We provide in-house programming and CAD drawing to create your specifications. During the process we monitor and inspect laser cut parts to ensure the products are made to your design and industry specifications.

Benefits over traditional cutting

One of the greatest benefits of laser cutting is the high level of precision it offers. The process utilises a high powered beam — also known as a laser — in order to cut the intended material. This process creates a precise cut allowing us to create more complex parts.

The precision and small turnaround times associated with laser cutting makes it an efficient, cost effective option.

Laser cut edges are also cleaner than those cut by more traditional methods.

In most cases the edges are cut so precisely that no further operations (deburring etc) are necessary. This reduces the amount of materials used, reducing the amount of waste.

Types of materials

The variety of materials that we can cut include:

No Comments

Sorry, the comment form is closed at this time.